Why Are Cut-to-Length and Slitting Lines So Important?

Cut-to-length and slitting lines are among the most critical processing stages in stainless steel production, as they enable the delivery of customer-specific solutions. By moving beyond production limited to standard dimensions, these lines allow stainless steel to be customized to precisely match the requirements of a project, an industry, and a specific application. This level of flexibility is a fundamental requirement of modern industrial manufacturing.

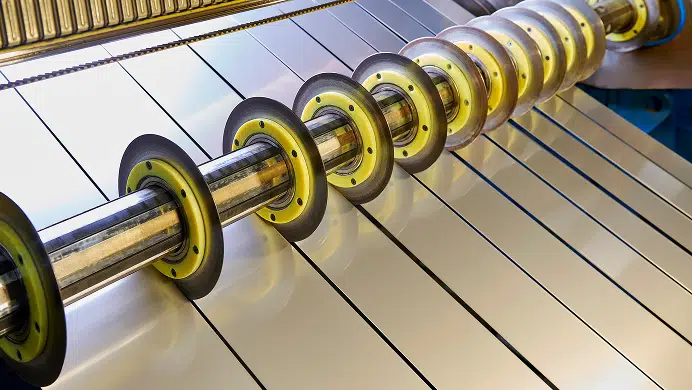

Slitting lines enable stainless steel coils to be cut with high precision into the required widths, while cut-to-length lines allow plate products to be prepared in exact lengths. These processes not only save time in production workflows but also minimize material waste. Stainless steel processed to precise dimensions eliminates the need for additional cutting or corrective operations in subsequent manufacturing stages.

Dimensional accuracy is particularly critical in sectors such as industrial kitchens, home appliances, and automotive manufacturing. In industries operating with millimetric tolerances, dimensional deviations can complicate assembly processes and lead to production errors. Stainless steel products cut to exact specifications accelerate assembly, reduce labor costs, and increase overall production efficiency. At the same time, lower scrap rates provide significant advantages in terms of both cost optimization and sustainability.

Advanced cut-to-length and slitting lines play a vital role not only in speed, but also in ensuring consistent quality. Digitally controlled systems continuously monitor cutting accuracy and ensure compliance with defined standards. This approach prevents quality fluctuations, especially in high-volume production environments.

At this point, Sarıtaş Stainless Steel delivers high-standard solutions in terms of dimensions, quality, and continuity through its advanced cut-to-length and slitting infrastructure.

In conclusion, cut-to-length and slitting lines are not merely technical processes in stainless steel production; they are strategic manufacturing elements that directly impact efficiency, quality, and customer satisfaction. They are indispensable components of modern stainless steel manufacturing.